rockwell hardness test knife blade|knife rockwell hardness chart : advice If you’ve bought a knife in the past, you’ve undoubtedly seen something like “HRC 56-58” in the specs. You may know that it represents the . • How LVDTs Work: an interactive explanation• Phasing Explanation• LVDT models and applications Ver mais

{plog:ftitle_list}

23 de fev. de 2024 · Gambling can be addictive, please play responsibly. U.S. Real Money Casinos Quick Facts. ⭐ Top casino operator. DraftKings Casino. 💰 Biggest welcome bonus. Caesars Palace - Deposit match up .

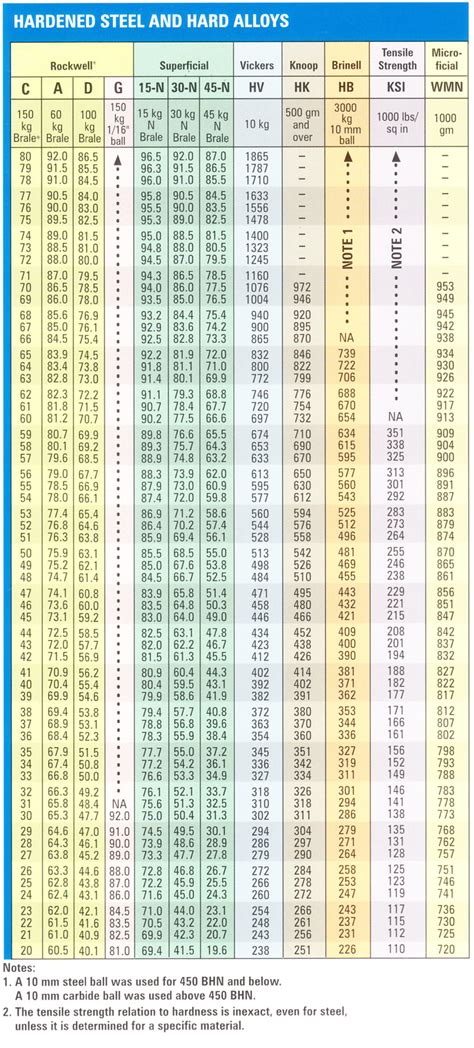

The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the . What is Rockwell Hardness Test? The Rockwell hardness test measures the resistance of a material to indentation. The indentation is made with a standardized ball indenter that has a flat circular shape and a radius of 25.4 .

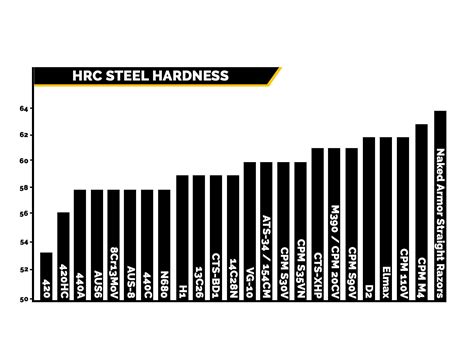

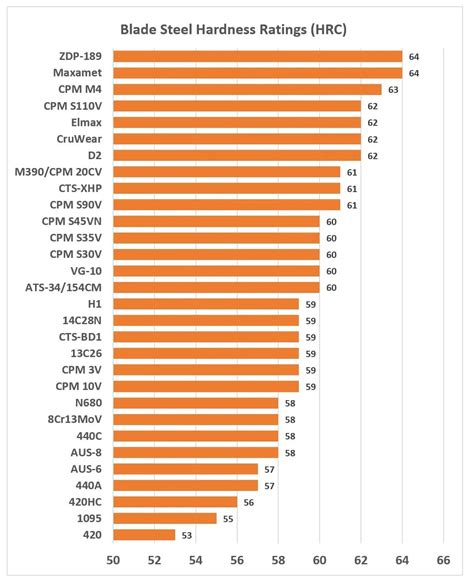

rockwell steel hardness

The Rockwell test helps knifemakers balance the three most important factors that can affect the quality of their finished product: hardness, flexibility, and . If you’ve bought a knife in the past, you’ve undoubtedly seen something like “HRC 56-58” in the specs. You may know that it represents the .The Rockwell hardness test uses a diamond-tipped indenter to measure material hardness, providing crucial insights into knife blade quality and performance. This method ensures .The important scale for knife steel is the Rockwell C Scale, often shown as HRC. Because it’s fast and reliable, the Rockwell method is the most popular hardness test for the stainless steel used to make knife blades.

The Rockwell Hardness Scale is a standardized measurement system used to determine the hardness or resistance to deformation of a material, especially metals. For kitchen knives, this scale is a crucial indicator of how .

In the knife industry, the Rockwell hardness test is typically used to measure the hardness of the blade at the spine and edge. The Rockwell scale used for knives is typically the C scale, which measures the hardness of . The most important (and commonly used) Rockwell scale for measuring the steel of knives is the Rockwell C Scale (also called an "HRC score"), which measures the steel’s resistance to permanent distortion.The Rockwell hardness test allows knifemakers to find a balance that promotes blade sharpness and helps the owner keep it that way. Generally, a knife with a Rockwell Hardness Scale rating of 58-60 will hold an edge better than a .It is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136° angle is used and the force and surface of the indented pyramid is measured. Mohs .

This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): .The Rockwell hardness test uses a conical indenter and is the most common test used for testing the hardness of different types of steel. However, the Rockwell test is not ideal for uneven materials with high levels of inconsistency across the surface. . Having enough toughness is vital for cutting tools, as it allows the knife or blade to .

The very good toughness of MagnaCut meant that it didn’t chip despite this relatively high hardness and the difficulty of the test. . I know that one does not normally make knife blades of titanium, but I gather that Ti is extremely corrosion resistant, used for saltwater applications, etc. . So for people making kitchen knives at 64 . The hardness level of steel is determined using a universal scale called the “Rockwell C Test”, commonly called the Rockwell hardness scale (HRC). Almost all consumer-grade pocket knives, EDC knives, fixed blade knives, etc will be in the range of a Rockwell Hardness rating of 54 to 65 HRC. Shun Knives Rockwell Hardness (HRC) HRC stands for Rockwell Hardness—a standardized method of measuring how hard any given steel is. The higher the number, the harder the steel. Your average German knife, made with German steel, comes in around HRC 57. Shun (with one exception that I know of) heat treats all its knives to HRC 60-61.

Wondering what the Rockwell scale even is? Read on for all you need to know. GRAB GORDON'S GOLDEN TICKET TO LONDON | LEARN MORE. . 16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle 9.99 4 22% Savings (157) Aprons Aprons. Eco Modern Apron Benny's Eco . Knife Reviews & Testing. Mercer Culinary Genesis 7 Inch Chef Knife; . including metal. In a culinary context, then, the Rockwell hardness rating (HRC) of a knife will tell you how hard and durable it is. The higher the number, the harder and stronger a given knife is. . If you need blade flexibility, buy a knife with a slightly lower HRC .Hardness, or HRC, is a metric referring to a steel's resistance to heat, stress, and other forces regularly applied to knives. The ability of steel to retain its original shape is measured on the Rockwell C scale, also known as Hardness Rockwell C (HRC). In general, a knife must have an HRC of at least 52 to be usable.The Rockwell hardness test employs a precise and standardized methodology to measure the hardness of metallic materials, including knife blades. The process involves using a diamond-tipped cone indenter that is pressed into the steel surface at two different pressure levels. . The most relevant scale for knife blades is the Rockwell C scale .

Using This Test For Knives. The hardness of a knife blade is an important factor in its performance. A blade, that is too soft, will not hold an edge, while a blade, that is too hard, may be brittle and prone to chipping or breaking. . In the knife industry, the Rockwell hardness test is typically used to measure the hardness of the blade at . HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness . Knife Reviews & Testing . Rockwell Hardness of Damascus? . . Rockwell Hardness of Damascus? Thread starter Confederate; Start date Nov 8, 2007; Status Not open for further replies. C. Confederate. Joined Sep 5, 2005 . The knife I posted a photo of above looks just like a Bear & Sons Damascus. Beautiful blade. But when I see a beautiful . The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration . if you hear the term, “differential temper” it means that the knife .

In all, the Rockwell hardness of a knife will always be different between high-end knives and low-end knives, for example, an M390 steel knife is a 62HCR compared to 420Hc steel knife which has a 58HCR, it doesn’t necessarily mean that the M390 is better than the 420HC, yes the M390 Is a premium steel with high quality, but it depends on your usage too, for example, both .

Knife Blades and Kits; Handle Materials; Shop All Products. Mega. Jantz Supply Digital Catalog. Blade Steel; 01 and W1 Drill Rod; 15N20 2% Nickel Steel; . Test the Rockwell Hardness of your blade quickly and easily. . How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..

The hardness levels of 420HC steel are typically tested using the Rockwell hardness scale (HRC). An optimum heat treatment process can result in 420HC steel achieving a hardness of approximately 55 HRC according to a datasheet from Alpha Knife Supply. The Rockwell hardness test measures the resistance of steel to indentation. Rockwell hardness tester. The tool we use to test hardness is called the Rockwell hardness tester. The Rockwell hardness tester applies an indentation force to the material being tested and measures the depth of penetration to determine its hardness value. . This method is widely accepted for testing corrosion in knife blades. It’s a .

rockwell knife hardness rating

You can't determine Rockwell hardness with a scratch test or vice versa. . and just field testing the blade for it's intended purpose probably makes the most sense for us humble knifemakers. Last edited: Oct 18, 2011. Tai Goo. BANNED. Joined Apr 7, 2006 Messages 3,806. Oct 18, 2011 #20 One difference between hardness testing steel with files .So Rockwell hardness testing works very well as a quality monitor for heat treating. What the Test Will Not Do Steels are heat treated to a specific microstructure and the Rockwell C scale is only a gross indicator of the microstructure of the steel and cannot be considered a direct indicator of whether a knife will be tough or take and hold a . The Rockwell hardness test is done by measuring the permanent depth created on a material caused by the force of the indenter. . It’s the opposite with kitchen knives with a softer hardness rating. The hard knife blades are surely a lot more fragile due to increased brittleness than knives with softer steel, but with enough care and caution .

An example is stainless steel AUS-8, which usually 57-59 Rc. The Rockwell hardness test is the industry standard for knives. . The important scale for knife steel is Hardness Rockwell Scale C, often shown as HRC, which is further abbreviated to just Rc. . The Boker Bailey Ziel throwing knife is pictured. These blades are Parens, or Spring .Civivi Rustic Gent Knife With D2 Steel Blade Introduction To D2 Knife Steel. When it comes to knife making, the quality of the steel is paramount, and D2 steel stands out for its toughness and the ability to maintain a sharp edge. . (Rockwell Hardness Scale). This range of hardness provides a good balance between edge retention and durability .

Attribute #5: Rockwell Hardness. . Check out Ankerson’s steel rankings for real world testing. Blade Steel Myth #4. A better steel won’t necessarily make a better knife. The steel may be the soul of the blade but the ergonomics are the heart. . This is one of the most thoroughly covered resources I have found on the subject of steel . The Rockwell test involves pressing a tiny, precisely shaped, sized indenter into the material's surface. The penetration depth is measured, giving us a hardness number. . Rockwell Hardness in Knife Manufacturing. . Knife manufacturers carefully select the appropriate Rockwell hardness for their blades based on their intended use.

larson spring tester dht 11 lb compression digital hand tester

rockwell hardness ratings

WEBBono de bienvenida de apuestas deportivas 888. La casa de apuestas deportivas 888 te regala $30 USD en apuestas gratis pero primero debes de depositar y apostar al menos $10 USD en cuotas mínimas de 1.50 (1/2). Mínimo depósito de $10 USD o el equivalente a tu moneda local. Una apuesta que califica es de dinero real y mínimo $10 USD.

rockwell hardness test knife blade|knife rockwell hardness chart